- toppage

- first-time visitors

printed circuit board design/production

printed circuit board design/production- Art Electronics' technology

- planning environmental response

- company overvuew

- inquiry

From design to mounting of printed circuit boards in the shortest time possible.

Art Electronics Co., Ltd. offers technical capabilities that are second to none.

Dividing orders between suppliers requires a great deal of work.

At Art Electronics Co., Ltd., we can handle everything from circuit design to mounting.

Our task is to support developers concentrating their original task of value-added development by eliminating the

time required to choose suppliers for design, circuit boards and mounting.

Art Electronics Co., Ltd. utilizes some of the best technology in Japan to develop printed circuit board prototypes.

All of our designers are nationally licensed, and provide services with an extremely high level of precision.

Furthermore, our customers are able to lower their costs by utilizing our services to reduce development times.

Development of hardware and software in support of product development.

Art Electronics Co., Ltd. utilizes technology

(our development support section is staffed by specialists

in both analog and high-speed digital technologies) and

information (through strong relationships with vendors of

many different system devices) to meet customer

requirements by providing the highest level of service in t

he shortest possible time.

We confirm customer development requirements, and meet

them by performing everything from circuit design through

to pattern design and mounting in-house.

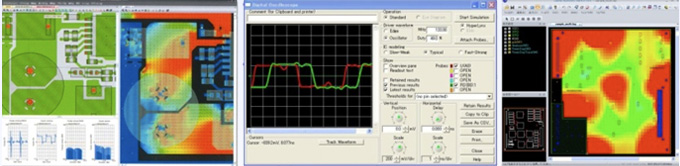

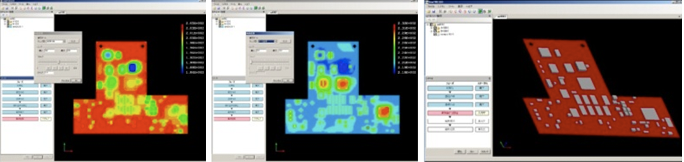

In pattern design, simulation design is used to counter

noise, and a DR (Design Review) is carried out based on

production technology capabilities using cutting plans and

mounting of circuit boards, following which proposals that

take technological and cost factors into account are made.

Languages supported

Visual C++ / Visual Basic / Assembler / Verilog / VHDL

Noise countermeasure design

Efforts to cleanliness

What is cleanliness?

A figure denoting the number of particles of dust and dirt with a diameter of 0.5u within one cubic foot of air.

(Units: Number/0.1 cf ) (Generally, this is measured over an floor space of approximately 1.4 m.Art Electronics also

utilizes this measurement.)

Thus, the lower the number, the cleaner the air in the room. Generally, even the better production facilities are in

the 200,000 - 300,000 class.Accordingly, a 100,000 class is indicative of a high level of control, equivalent to that

of a vehicle mass production fitting company.

Provision of in-house inventory parts (more than 3,000 standard items)

Extensive procurement routes (inside and outside Japan) allow for rapid

delivery of purchased parts

0402-type chip mounting-capable BGA CSP

All BGA mountings are inspected by X-ray (AOI inspection carried out on other circuit boards)

Wrapping mounting

Flip chip mounting, wire bonding

CAD system sales

Comprehensive after-sales care

| ▲Back to top | |

Art Electronics Co., Ltd. Hamamatsu City, Shizuoka Prefecture, Chuo-ku, Higashimikata town 23-5 Art Techno House

|http://www.art-denshi.co.jp/|Privacy Policy|

Copyright c 2013 By Art Electronics Co., Ltd. All Rights Reserved.